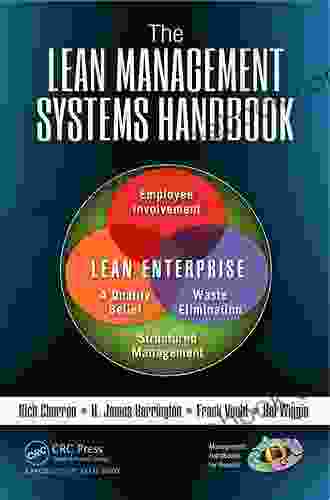

The Lean Management Systems Handbook: Unveiling the Principles and Practices of Lean Manufacturing

In an era marked by intense competition and ever-changing market dynamics, organizations are constantly seeking ways to improve their efficiency, reduce waste, and enhance customer satisfaction. Lean Management Systems have emerged as a powerful approach to achieving these objectives, enabling organizations to achieve remarkable results through the elimination of waste and the pursuit of continuous improvement.

4.7 out of 5

| Language | : | English |

| File size | : | 29689 KB |

| Screen Reader | : | Supported |

| Print length | : | 549 pages |

The Lean Management Systems Handbook is the definitive guide to understanding and implementing Lean principles and practices in manufacturing environments. This comprehensive handbook provides a thorough overview of the Lean philosophy, its core concepts, and the practical tools and techniques used to implement Lean systems.

Key Concepts of Lean Management

1. Customer Focus

Lean systems prioritize the needs and expectations of customers, ensuring that every process and activity is designed to meet customer requirements. This customer-centric approach drives all aspects of Lean implementation, from product design to production planning.

2. Waste Elimination

Lean systems relentlessly focus on identifying and eliminating waste in all its forms. Waste is defined as any activity or process that does not add value to the customer. Lean practitioners use various tools, including value stream mapping, to identify and eliminate waste, leading to significant improvements in efficiency and cost reduction.

3. Continuous Improvement

Lean systems embrace a culture of continuous improvement, known as Kaizen. This ongoing process involves regularly evaluating current practices, identifying areas for improvement, and implementing changes to enhance efficiency and effectiveness. Kaizen empowers employees at all levels to contribute to the improvement process.

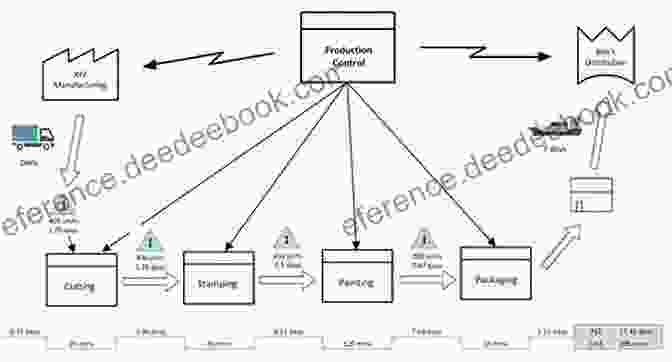

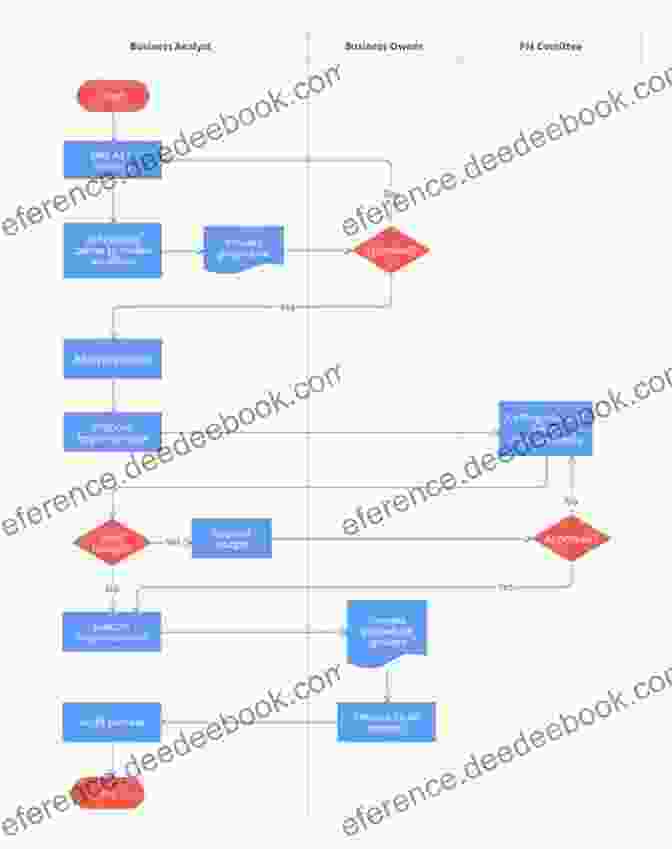

4. Value Stream Mapping

Value stream mapping is a powerful tool used in Lean systems to visualize and analyze the flow of materials and information through a process. This visual representation helps identify waste, bottlenecks, and opportunities for improvement, enabling organizations to optimize their production processes.

5. Just-in-Time Production

Just-in-Time (JIT) production is a key component of Lean systems, aimed at eliminating waste by producing products only when they are needed. JIT systems minimize inventory levels, reduce lead times, and improve production flexibility, resulting in significant cost savings and increased customer responsiveness.

Tools and Techniques of Lean Management

The Lean Management Systems Handbook provides detailed descriptions of the essential tools and techniques used to implement Lean systems, including:

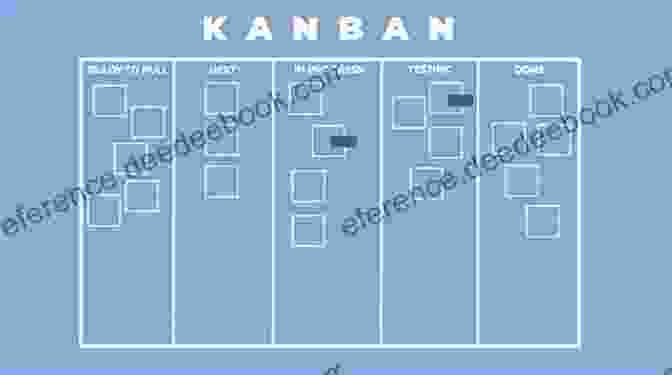

1. Kanban

Kanban is a visual management system that limits work-in-process inventory and ensures smooth production flow. Kanban cards represent customer orders and are used to pull products through the production process, eliminating overproduction and reducing lead times.

2. Andon

Andon is a visual signaling system used to alert operators to problems or abnormalities in the production process. When a problem occurs, the operator activates an Andon light or cord, which notifies supervisors and triggers immediate corrective action, preventing defects and minimizing downtime.

3. Poka-Yoke

Poka-Yoke is a mistake-proofing technique that prevents errors from occurring in the production process. It employs physical or procedural barriers to eliminate the possibility of human error, ensuring quality and safety.

4. Jidoka

Jidoka is an automation technique that automatically stops a machine when a defect is detected. This prevents defective products from being produced and alerts operators to the problem, enabling immediate corrective action.

5. Standard Work

Standard Work is a detailed description of the best way to perform a task, based on the principles of time and motion study. Standard Work ensures consistency, reduces variability, and improves production efficiency.

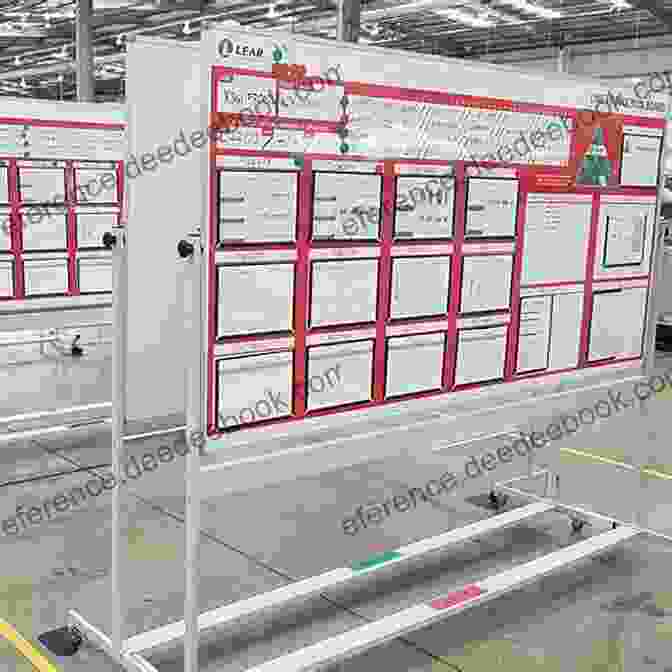

6. Visual Management

Visual Management uses visual cues, such as charts, graphs, and看板(kanban),to display information and communicate key performance indicators (KPIs) throughout the workplace. This promotes transparency, facilitates problem-solving, and creates a visually organized and efficient environment.

Case Studies and Success Stories

The Lean Management Systems Handbook includes numerous case studies and success stories from organizations that have successfully implemented Lean principles and achieved remarkable results. These case studies provide valuable insights into the practical application of Lean tools and techniques, demonstrating the transformative power of Lean management in various industries.

The Lean Management Systems Handbook is an invaluable resource for organizations seeking to improve their manufacturing processes, reduce waste, and enhance customer satisfaction. By providing a comprehensive understanding of the principles, tools, and techniques of Lean management, this handbook empowers readers to implement Lean systems effectively and reap the benefits of increased efficiency, reduced costs, and improved quality.

4.7 out of 5

| Language | : | English |

| File size | : | 29689 KB |

| Screen Reader | : | Supported |

| Print length | : | 549 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Page

Page Chapter

Chapter Text

Text Genre

Genre Paperback

Paperback E-book

E-book Paragraph

Paragraph Sentence

Sentence Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Synopsis

Synopsis Footnote

Footnote Manuscript

Manuscript Tome

Tome Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Encyclopedia

Encyclopedia Dictionary

Dictionary Thesaurus

Thesaurus Narrator

Narrator Character

Character Resolution

Resolution Librarian

Librarian Archives

Archives Study

Study Research

Research Lending

Lending Journals

Journals Reading Room

Reading Room Rare Books

Rare Books Interlibrary

Interlibrary Storytelling

Storytelling Awards

Awards Reading List

Reading List Book Club

Book Club Textbooks

Textbooks Charles L Glaser

Charles L Glaser Matt Artz

Matt Artz Susan C W Abbotson

Susan C W Abbotson Ebony Brown

Ebony Brown Codex Regius

Codex Regius Ian Penman

Ian Penman Margaret Thomson

Margaret Thomson Ron Berger

Ron Berger Jenny Smedley

Jenny Smedley Jakub J Grygiel

Jakub J Grygiel James M Jasper

James M Jasper Donovan R Walling

Donovan R Walling Neil A Hogan

Neil A Hogan Michael Wright

Michael Wright Brandon Vallorani

Brandon Vallorani Sergio Marchi

Sergio Marchi Donna Soto Morettini

Donna Soto Morettini Alexandre Dumas

Alexandre Dumas Matthew Vale

Matthew Vale John Heaton

John Heaton

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Angelo WardFollow ·10.5k

Angelo WardFollow ·10.5k Guillermo BlairFollow ·18.8k

Guillermo BlairFollow ·18.8k Eric HayesFollow ·19.3k

Eric HayesFollow ·19.3k David BaldacciFollow ·15k

David BaldacciFollow ·15k Grant HayesFollow ·13.9k

Grant HayesFollow ·13.9k Roy BellFollow ·4.3k

Roy BellFollow ·4.3k Denzel HayesFollow ·3.5k

Denzel HayesFollow ·3.5k Ervin BellFollow ·8.3k

Ervin BellFollow ·8.3k

Hector Blair

Hector BlairUnderstanding How to Build Guitar Chords and Arpeggios: A...

Mastering guitar chords and arpeggios...

Charles Dickens

Charles DickensClosing the Shocking Education Gap for American Children:...

Education is the foundation...

Billy Peterson

Billy PetersonAny Rogue Will Do: A Captivating Adventure in the...

Step into the...

Ricky Bell

Ricky BellMastering Sight Words Level 1: A Comprehensive Guide for...

In the realm...

4.7 out of 5

| Language | : | English |

| File size | : | 29689 KB |

| Screen Reader | : | Supported |

| Print length | : | 549 pages |